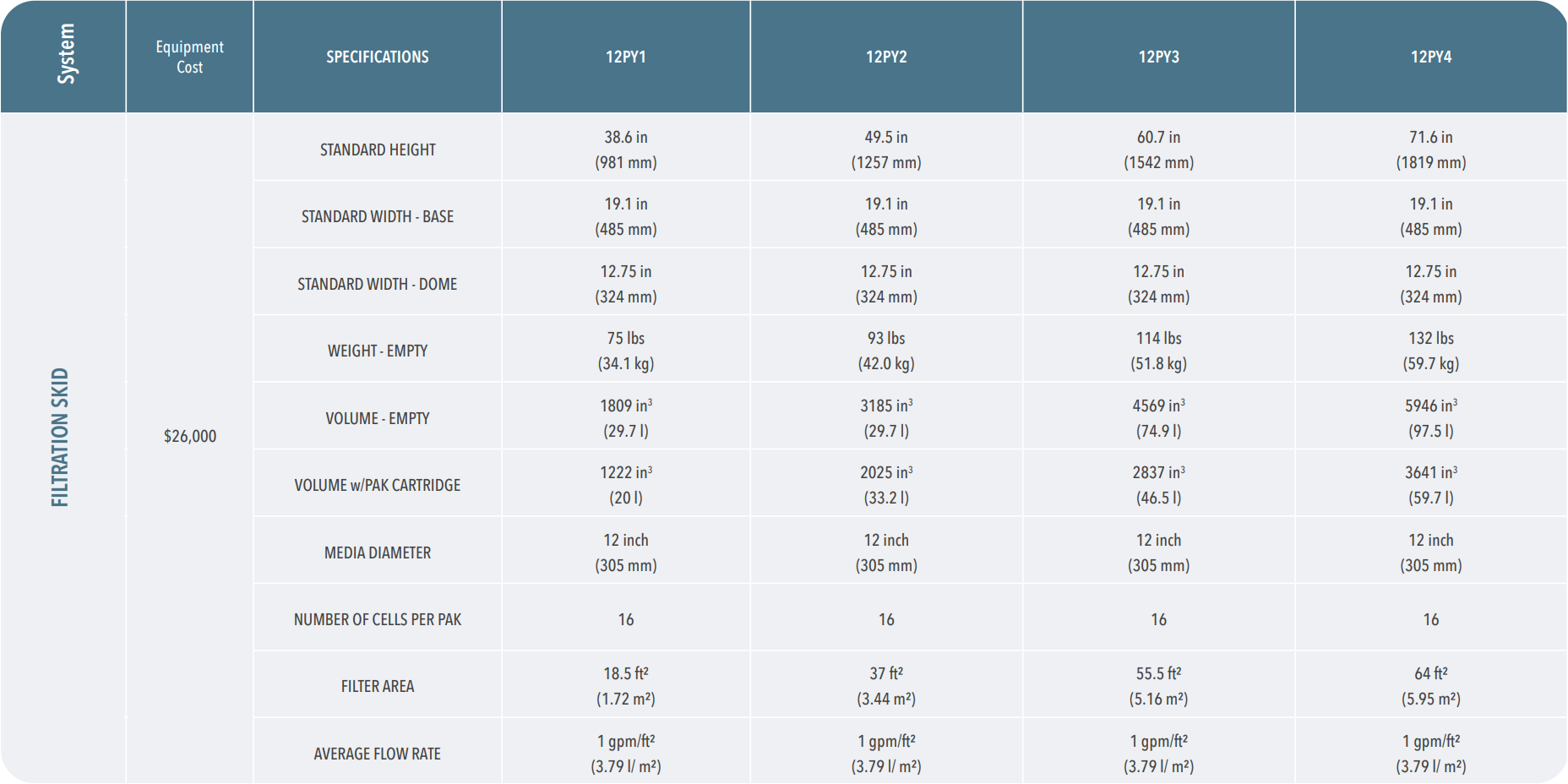

The four-stage filtration skid is used in the post-processing stage of the ethanol extraction process to clean up any unwanted plant particles, pigments (carotenoids, chlorophyll, etc.), and lipids from your tincture. Within the impregnated lenticular filters, you can use any filtration media you require, such as activated carbon, magnesium silicate, diatomaceous earth, or zeolite for color remediation.

View our recommended ancillaries list by using the direct link below.

Address

Delta Separations

525 Portal St.

Cotati,

CA

94931

(707) 222-6066

sales@deltasepaprod.wpengine.com

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.