Service Plans

Maintenance Plans for all your Ethanol Extraction Equipment

It pays to keep your ethanol equipment in good shape! Protect your investment and improve outputs with our annual maintenance and service plans. Choose from virtual or on-site service plans and avoid any costly disruptions to your operation.

- Extraction: CUP-15 and CUP-30

- Evaporation: FFE-45 and FFE-60

- Distillation: RFD-27

*All plans include parts and service unless otherwise specified.

CUP-15 Annual Maintenance Plan

Remote video call w/parts provided or on-site

* Price per unit/year

Included Actions:

- Replace all sanitary gaskets

- Replace lid gasket

- Inspect lid hinge welds

- Inspect HMI stand welds

- Check belt tension (direct to replace if necessary)

- Inspect isolators (direct to replace if necessary)

- Flush barrier fluid

- Replace sight glass gaskets

- Remove basket and inspect seals

- Inspect bearing runout

- Inspect valve assemblies

- Inspect all tubing and piping

- Replace PRVs

- Update firmware – if required (on-site)

**CUP-15: 15% discount on replacement drive for up to one year following warranty expiration

CUP-30 Annual Maintenance Plan

Remote video call w/parts provided or on-site

* Price per unit/year

Included Actions:

- Replace all sanitary gaskets

- Replace lid gasket

- Inspect lid gas struts

- Remove basket and inspect seals

- Check bearing runout

- Inspect lid hinge welds

- Check belt tension (direct to replace if necessary)

- Inspect isolators (direct to replace if necessary)

- Inspect all tubing and piping

- Inspect collection vessel

- Replace sight glass gaskets

- Replace PRVs

- Verify vibe sensor

- Update firmware – if required (on-site)

**CUP-30: 15% discount on replacement drive for up to one year following warranty expiration

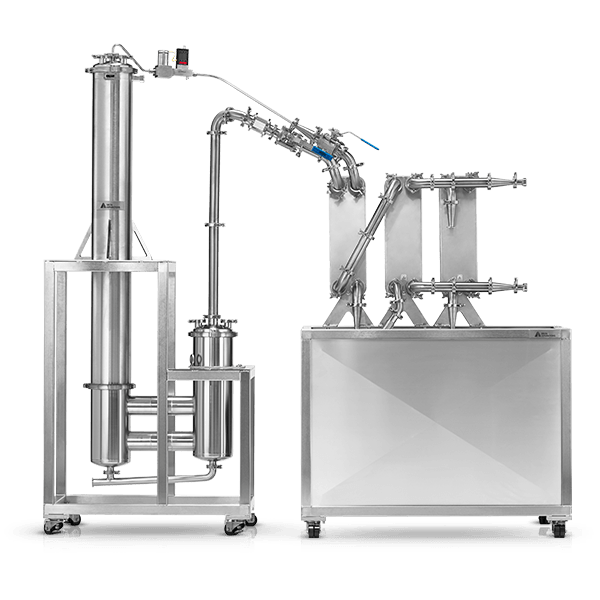

FFE-45 & FFE-60 Annual Maintenance Plan

On-site w/parts provided

* Price per unit/year

Included Actions:

- Replace all sanitary gaskets (~100 gaskets)

- Inspect motor to pump bushing

- Inspect inside of evaporative column, clean if necessary

- Inspect all rubber tubing, replace if necessary

- Check fluid levels and concentrations (direct to replace if contaminated)

- Check for leaks/potential problem points with heaters and chillers

- Verify all electrical connections

- Replace filter

- Perform all technical service bulletins

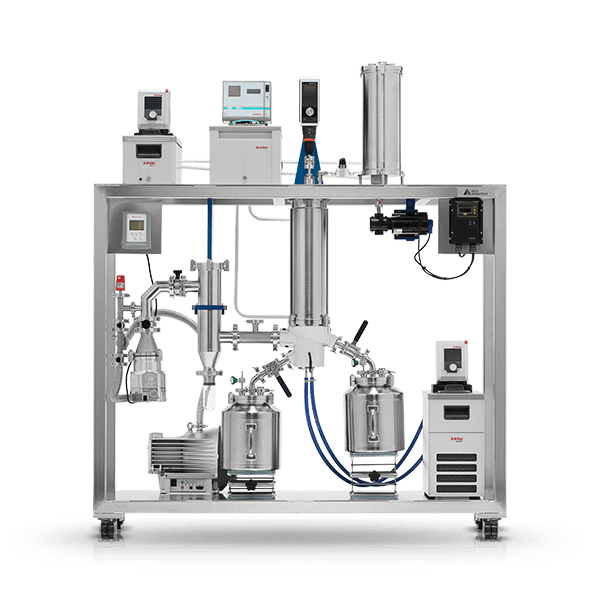

RFD-27 Annual Maintenance Plan

On-site w/parts provided

* Price per unit/year

Included Actions:

- Replace rollers

- Replace seals between gear pump and feed tank

- Replace cold trap seals

- Disassemble entire unit, clean thoroughly

- Inspect feed through plate (replace bearings and seals if necessary)

- Inspect all heat transfer fluid (direct to replace if contaminated)

- Inspect turbo

- Inspect scroll pump

- Verify concentricity of roller cage

- Verify heat display to main body temp

- Perform standalone vacuum levels on scroll pump and turbo pump

- Replace seals on main Evap body

- Replace KF seals

- Replace clamps on main Evap body

- Perform all technical service bulletins