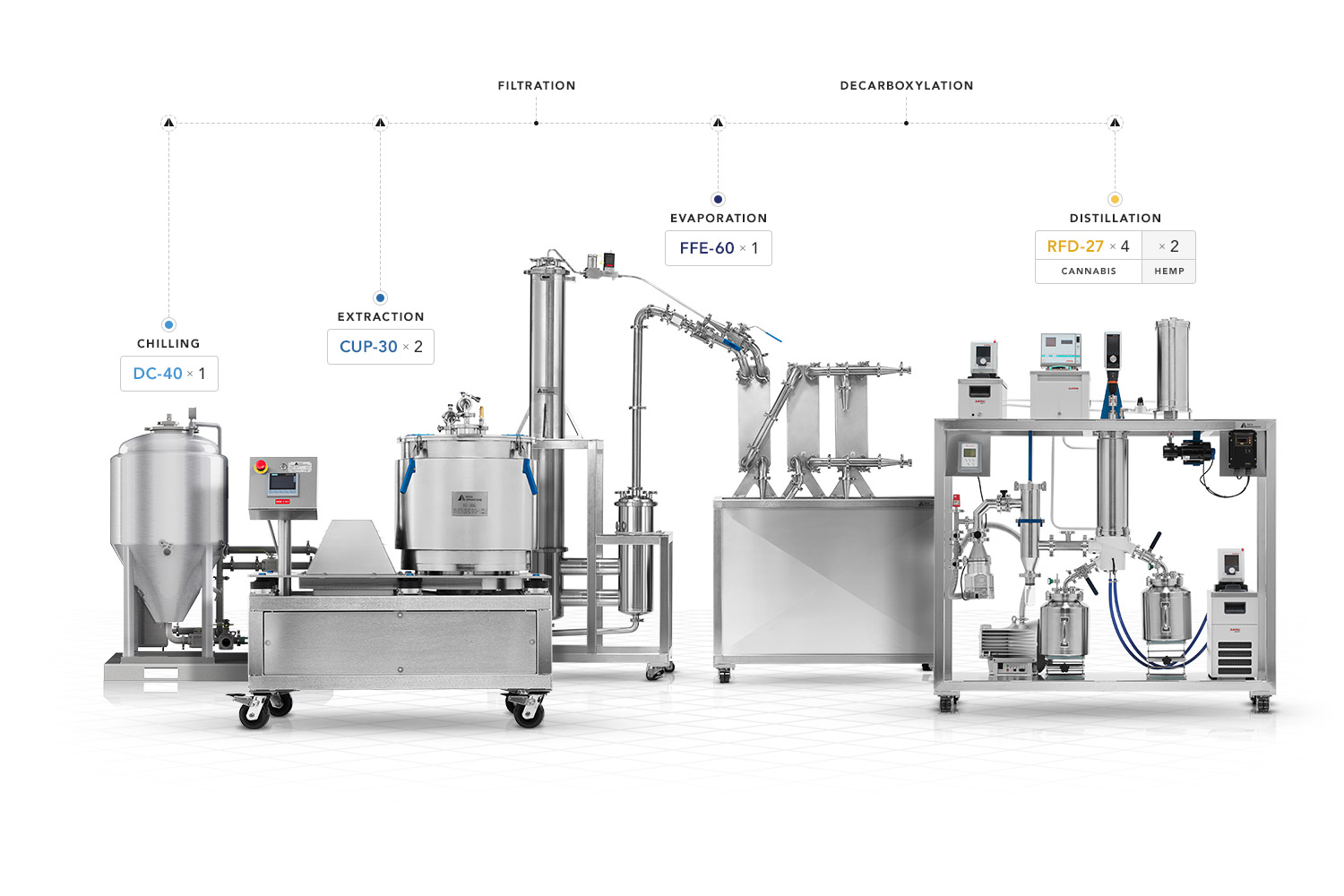

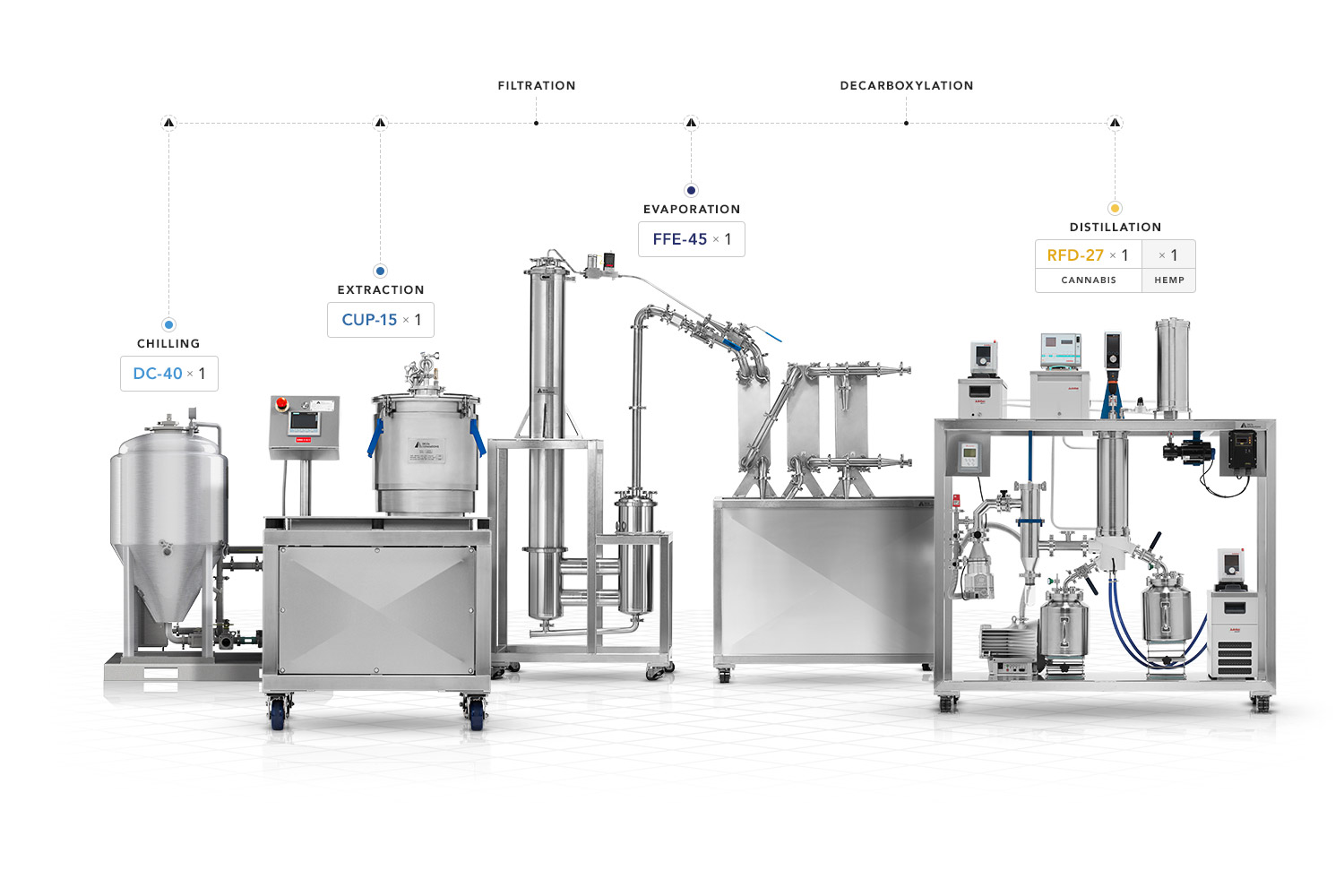

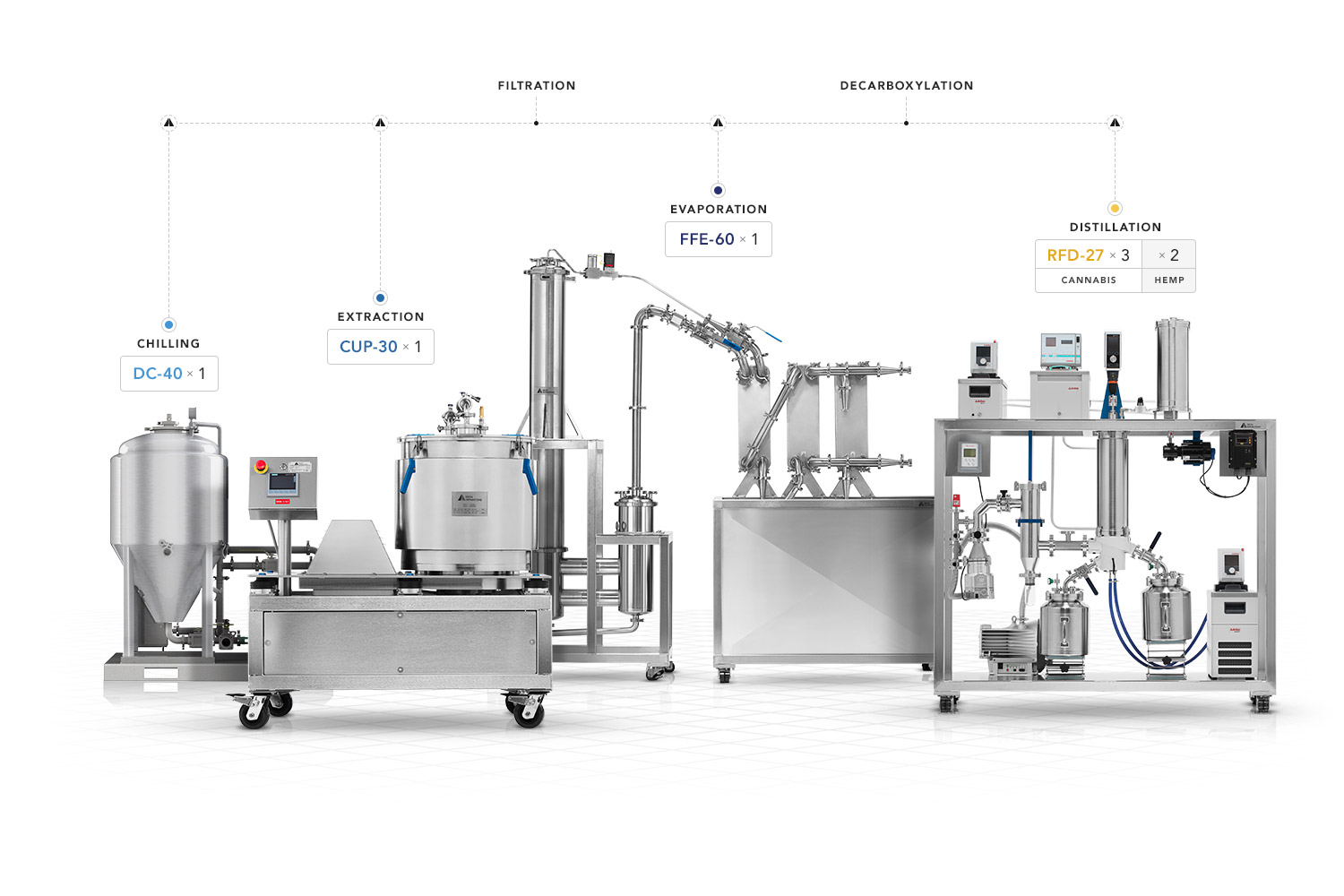

System Configurations

Herein is pictured the full cold ethanol processing suite ordered to follow the solvent/extract as it passes through the Direct Chiller, Centrifugal Utility Platform extractor, Falling Film Evaporator, and Rolled Film Distiller. The ancillary gear depicted in the lineup includes the single lenticular filtration solution, a decarboxylation reactor, and a rotary evaporator for residual solvent reclamation; while Delta Separations does not manufacture these components, we collaborate with trusted manufacturers to provide a highly functional and premium experience. This process flow is modular, and is the first gear of it’s kind to be UL1389 compliant.

Cold Ethanol Extraction

300lbs / Shift * Recommended equipment and throughput may vary depending on your SOP, biomass, and facility configuration.

Cold Ethanol Extraction

600lbs / Shift * Recommended equipment and throughput may vary depending on your SOP, biomass, and facility configuration.

Cold Ethanol Extraction

1200lbs / Shift * Recommended equipment and throughput may vary depending on your SOP, biomass, and facility configuration.